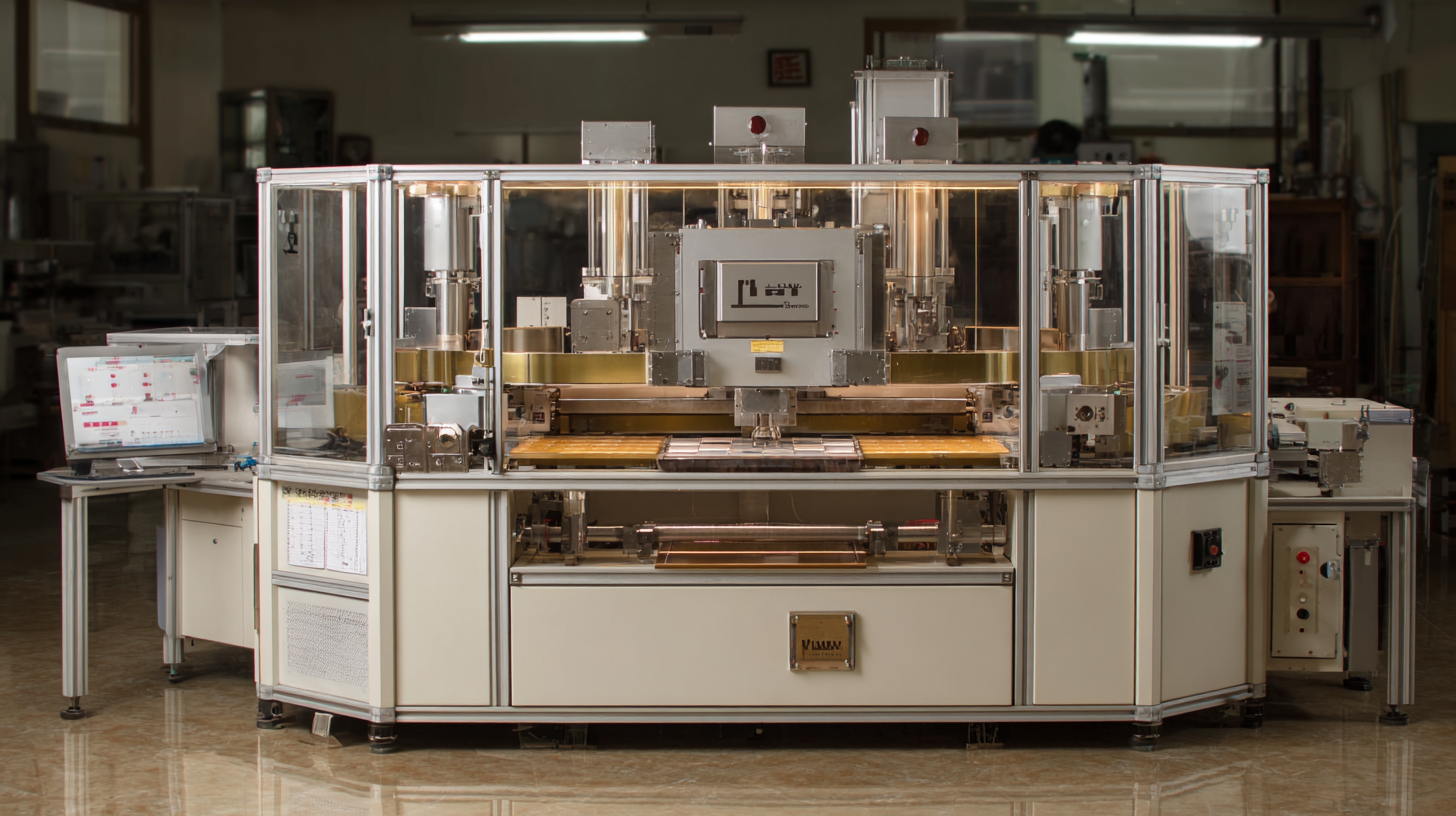

In the world of confectionery, the quality of chocolate and its presentation play a critical role in captivating consumers and enhancing the overall experience. The Chocolate Enrobing Machine stands at the forefront of this transformation, expertly coating various confections in rich, decadent chocolate with precision and artistry. Crafted to meet the highest international standards, these cutting-edge machines are meticulously designed and manufactured in China, ensuring not only global excellence but also accessibility for businesses around the world. This blog will delve into the detailed technical specifications of these machines, highlighting their features, capabilities, and the innovative technologies that make them an essential tool for chocolate manufacturers. Additionally, we’ll provide a comprehensive guide on how to maximize the potential of your Chocolate Enrobing Machine for superior results that elevate your products and delight your customers.

The global chocolate enrobing market is experiencing exponential growth, driven by rising consumer demand for premium chocolate products. Recent market research indicates that the chocolate enrobing machine industry is projected to expand at a CAGR of 6.8% from 2023 to 2030, reflecting an increasing inclination towards automation and efficiency in production. As manufacturers seek to optimize their production lines, the demand for world-class enrobing machines has never been higher, particularly those that offer versatility and precision.

When investing in chocolate enrobing machines, it is crucial to consider key features that enhance output and quality. One tip is to select machines equipped with adjustable temperature controls, ensuring the chocolate maintains its optimal texture during the sealing process. Additionally, look for machines that offer easy integration with existing production lines to streamline operations. Another valuable tip is to assess the machine's energy efficiency, as this can significantly impact operational costs over time.

As Chinese manufacturers continue to innovate and improve their technology, they are establishing a strong foothold in the global market. With advanced engineering and competitive pricing, these machines are meeting the needs of chocolate producers worldwide while adhering to international standards of excellence. The combination of quality and cost-effectiveness positions Chinese manufacturers as leaders in the chocolate enrobing machinery sector.

When it comes to chocolate production, the enrobing process is crucial for creating that perfect coating. High-quality chocolate enrobing machines manufactured in China are making significant strides in the global market, driven by advances in technology and an emphasis on precision. According to a recent report from Research and Markets, the global chocolate processing equipment market is expected to reach USD 4.5 billion by 2025, with a significant contribution from enrobing machines that enhance efficiency and quality.

Chinese manufacturers are setting benchmarks with their enrobing machines, which feature advanced temperature control systems to maintain optimal chocolate viscosity, ensuring a smooth and even coating. Additionally, these machines often incorporate user-friendly interfaces and automation features, which reduce operational labor and minimize waste. A study by Grand View Research indicates that user demand for such sophisticated equipment is rising, pushing manufacturers to innovate continually and enhance their offerings. This commitment to quality and precision places Chinese enrobing machines at the forefront of the chocolate industry, appealing to manufacturers worldwide.

The global chocolate manufacturing technology sector is experiencing remarkable growth, driven by rising consumer demand for premium products and innovative flavors. According to a report by Mordor Intelligence, the chocolate market is projected to grow at a CAGR of 4.89% during the forecast period of 2021-2026. This trend underscores the urgent need for advanced chocolate enrobing machines, which are pivotal in enhancing production efficiency and product quality.

To stay competitive in this thriving market, manufacturers are increasingly turning to state-of-the-art technology. With features like precise temperature control and automatic coating options, modern enrobing machines significantly reduce production time and minimize waste. As noted by Research and Markets, advancements in automation and smart manufacturing technologies are reshaping the landscape, enabling higher versatility and customization in chocolate production.

**Tips:** When investing in chocolate enrobing machines, consider models that offer flexibility in handling various types of chocolate and inclusions. Additionally, regular maintenance is key to ensuring optimal performance and longevity of the equipment. Finally, keep an eye on emerging packaging technologies that can complement your enrobing processes to attract a broader audience.

The chocolate enrobing industry is witnessing remarkable advancements, particularly with the rise of Chinese manufacturers who are setting new standards in the global market. Chinese chocolate enrobing machines are designed with cutting-edge technology that emphasizes efficiency, precision, and scalability. This has allowed them to compete with traditional leaders in the manufacturing sector, prompting a reevaluation of global enrobing standards. By examining the key features and operational capabilities of these machines, one can understand the significant role China plays in enhancing chocolate production processes.

When considering the comparison between Chinese and global chocolate enrobing machines, it is vital to focus on a few critical aspects. First, pay attention to the machine's adaptability to different types of chocolate and coatings. A machine that can switch seamlessly between various products will provide greater flexibility in manufacturing. Second, energy efficiency should not be overlooked; modern enrobing machines from China are designed to use less energy while maintaining high performance, aligning with global sustainability goals.

Tip: Always assess the after-sales support and warranty offered by the manufacturer. A reliable partner will ensure ongoing maintenance and quick resolutions to any operational challenges, safeguarding your investment. Additionally, consider investing in training for your staff to optimize the use of new enrobing technology, making sure you fully capitalize on the advantages provided by these sophisticated machines.

In the world of confectionery, production efficiency is key to success, and advanced enrobing techniques play a crucial role in achieving that goal.

Chocolate enrobing machines are an essential part of the process, allowing manufacturers to envelop their products in a smooth layer of chocolate with precision and speed.

These machines, crafted with state-of-the-art technology, not only optimize the coating process but also ensure uniformity and consistency in every piece of chocolate.

China has emerged as a leader in the manufacturing of these world-class enrobing machines, offering innovative solutions that cater to the needs of global markets.

By integrating smart technology and automation features, these machines significantly reduce production time and minimize waste, thereby enhancing overall productivity.

With features like adjustable speed settings and temperature controls, manufacturers can optimize recipes, reduce energy consumption, and achieve the perfect chocolate finish, ultimately leading to higher customer satisfaction and increased profit margins.

Investing in advanced enrobing technology not only elevates the brand's quality but also positions it as a forward-thinking player in the competitive confectionery landscape.

As companies seek to streamline their operations and enhance product offerings, the choice of enrobing machines will undoubtedly influence their success in the global market.

For more information, fill out our contact form