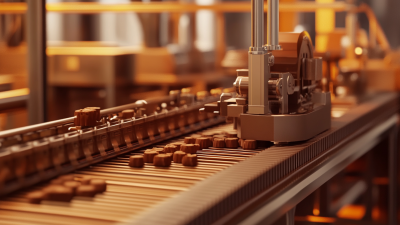

In the ever-evolving landscape of confectionery manufacturing, the role of the Chocolate Production Machine is crucial in meeting the soaring global demand for chocolate, which reached over 7.3 million metric tons in 2022, according to the International Cocoa Organization. As consumers increasingly seek high-quality and diverse chocolate products, understanding the intricacies of these machines becomes essential for manufacturers aiming to enhance efficiency and product quality.

This article will delve into the fascinating mechanisms and technologies behind chocolate production machines, from refining cocoa beans to shaping the final product. With advancements in automation and precision engineering, leveraging these machines not only optimizes production processes but also ensures that the delectable treats reaching consumers maintain a standard of excellence.

Join us as we unveil the secrets behind these remarkable machines that play a pivotal role in bringing sweet indulgence to chocolate lovers worldwide.

The evolution of chocolate production machines has significantly influenced the industry, transforming both quality and efficiency. From the rudimentary grinding stones used in ancient Mesoamerica to the sophisticated multi-functional machines of today, the chocolate-making process has advanced remarkably. According to a report by IBISWorld, the chocolate manufacturing industry in the U.S. is projected to reach $6.8 billion in revenue by 2024, illustrating the high demand for chocolate and the corresponding need for advanced production techniques.

Modern chocolate production machines incorporate state-of-the-art technology to improve not only the texture and flavor but also the overall operational efficiency. For instance, tempering machines have evolved from manual processes to automated systems that ensure consistent quality while minimizing human error. The International Confectionery Association highlights that automation and improved mixing technologies have enhanced production speeds by up to 30%, enabling manufacturers to meet growing consumer expectations for quality and variety. As the chocolate market continues to expand, investment in innovative machinery remains a key factor determining success within this delicious sector.

| Machine Type | Function | Capacity (kg/h) | Year of Invention | Key Innovation |

|---|---|---|---|---|

| Conching Machine | Mixing and refining chocolate | 500 | 1879 | Improved texture and flavor |

| Melting Tank | Melting cocoa butter and chocolate | 1000 | 2000 | Continuous heating system |

| Tempering Machine | Controlling crystal structure of chocolate | 300 | 1980 | Automated temperature control |

| Molding Machine | Forming chocolate bars and shapes | 250 | 1990 | High-speed operation |

| Packaging Machine | Packaging finished chocolate products | 1500 | 2005 | Robotic arms for efficiency |

The production of chocolate demands a harmonious blend of traditional craftsmanship and advanced technology, which plays a crucial role in ensuring both quality and consistency. At the heart of this process are various machines that help in crucial stages such as conching, tempering, and molding. Conching machines, for instance, not only refine the chocolate's texture but also enhance its flavor by continuously aerating the mixture. This refinement process is essential for producing that smooth, velvety quality known to chocolate lovers around the world.

Another key technology in chocolate production is the tempering machine, which stabilizes the cocoa butter crystals in chocolate. By carefully controlling temperature fluctuations, these machines enable manufacturers to produce chocolate that has a perfect gloss, snap, and melt-in-the-mouth texture. Additionally, automated molding and cooling systems ensure that each batch of chocolate meets strict industrial standards for consistency and quality. Together, these technologies not only improve efficiency but also elevate the overall chocolate-making process, producing delectable treats that delight consumers while maintaining a commitment to quality.

In the world of chocolate production, a variety of machines play crucial roles in transforming raw ingredients into the delectable treats we love. The chocolate-making process involves several steps, each requiring specific machinery. For instance, bean-to-bar operations necessitate equipment for roasting, winnowing, grinding, and conching. According to a report from Research and Markets, the global chocolate processing machinery market was valued at approximately $4.55 billion in 2022 and is projected to grow significantly, driven by increasing consumer demand for high-quality and artisanal chocolate.

Among the key types of machines used in chocolate production are tempering machines, which maintain the chocolate at the ideal temperature to achieve a smooth texture and glossy finish. Additionally, enrobing machines coat confections with a thin layer of chocolate, enhancing both flavor and appearance. A study by Allied Market Research indicates that the enrobing machine segment is expected to witness a compound annual growth rate (CAGR) of 7.5% from 2023 to 2030, highlighting the rising trend in chocolate confectionery innovations. Understanding these machines and their functionalities is essential for manufacturers looking to optimize production and meet the evolving tastes of consumers.

Maintaining chocolate production equipment is crucial for ensuring the smooth running of operations and delivering high-quality treats. According to a recent report, nearly 70% of production downtime can be attributed to equipment failure, highlighting the importance of regular maintenance. Routine checks such as lubrication of moving parts, calibration of machinery, and cleaning to avoid cross-contamination are essential practices that can extend the lifespan of machines and improve efficiency.

Moreover, proactive maintenance strategies can lead to significant cost savings. The Maintenance Cost Effectiveness Benchmark Report indicates that companies that implement a scheduled maintenance program can reduce repair costs by up to 30%. Simple actions like monitoring temperature settings for chocolate tempering machines, ensuring proper alignment, and using high-quality inputs can drastically improve both the performance of production equipment and the quality of the final product. By focusing on these critical aspects, manufacturers can optimize their operations and maintain their reputation for delicious chocolate treats.

The future of chocolate machinery is set to embrace innovative trends that focus on efficiency, sustainability, and precision. Manufacturers are increasingly integrating smart technology into chocolate production equipment, allowing for real-time monitoring and adjustments to production processes. This IoT-enabled machinery not only streamlines operations but also minimizes waste, ensuring that every morsel of chocolate is crafted with care. The rise of automation is making it possible to maintain high-quality standards while significantly boosting output.

Sustainability is another crucial aspect driving advancements in chocolate machinery. Companies are exploring eco-friendly materials and energy-efficient technologies to reduce their carbon footprint. As consumer demand grows for ethically produced chocolate, machines that can support bean-to-bar processes with minimal environmental impact will become more prevalent. Furthermore, innovations such as 3D chocolate printers are paving the way for personalized treats, allowing for creative designs that were once unimaginable. As these trends continue to evolve, the chocolate industry stands ready to deliver not just delicious treats, but also a commitment to responsible production practices.

For more information, fill out our contact form