When it comes to the world of chocolate production, selecting the right equipment can make all the difference, particularly when it comes to the Chocolate Enrobing Machine. This essential piece of machinery is crucial for creating that perfect chocolate coating that elevates confections from ordinary to extraordinary. However, buyers often face several challenges in choosing a machine that adequately meets their specific needs. From understanding the various types of enrobing machines available to knowing the right specifications that ensure optimal performance, the decision-making process can be overwhelming. This blog will delve into common issues encountered by buyers when selecting the best Chocolate Enrobing Machine and provide a comprehensive checklist to facilitate informed choices, thus ensuring your chocolate production journey is as smooth and successful as possible.

When selecting the best chocolate enrobing machine, buyers must consider several key factors that significantly influence their decision. Primarily, the tempering process stands out as a crucial precursor to successful enrobing. Properly tempered chocolate ensures a smooth, glossy finish and optimal texture, enhancing the overall quality of the confections. Understanding the intricate relationship between tempering and enrobing can help buyers choose machines that not only meet their production needs but also promote the exceptional characteristics of their chocolate products.

Additionally, it is essential to evaluate the machine’s capacity, ease of use, and maintenance requirements. The integration of advanced technologies can streamline the enrobing process, allowing for consistent results and higher throughput. Buyers should seek machines equipped with user-friendly controls and automated features that facilitate a seamless workflow. Furthermore, considering the sustainability and energy efficiency of the machinery can play a significant role in modern confectionery production, as businesses increasingly focus on minimizing their environmental impact while optimizing performance.

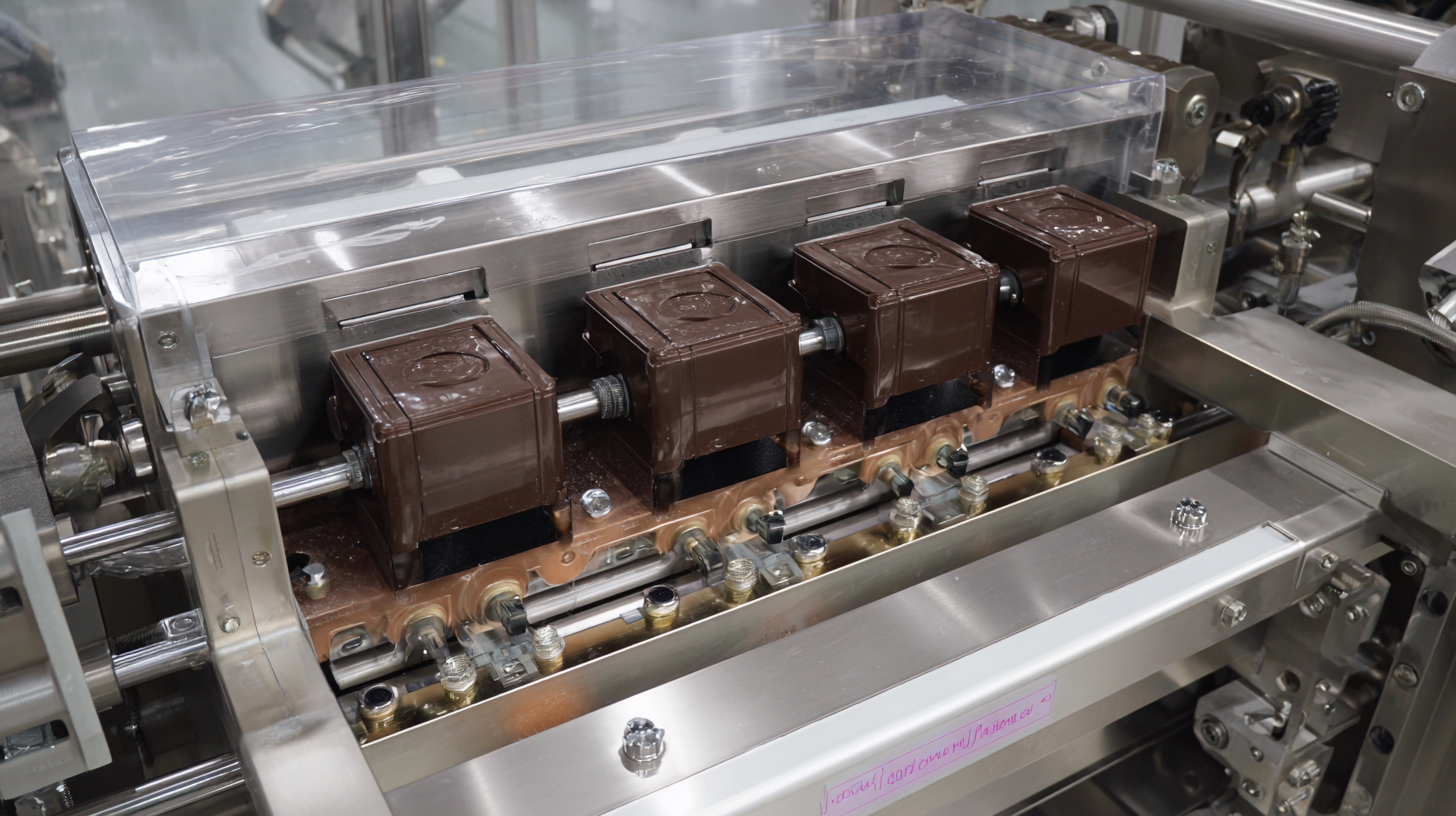

When it comes to selecting the ideal chocolate enrobing machine, understanding the various types available on the market is crucial. Each machine has unique features designed to cater to different production needs and chocolate types. For instance, there are continuous enrobing machines that provide high efficiency for large-scale operations. These machines ensure a consistent coating thickness and are perfect for chocolate-covered snacks or confectioneries. Typically, they come equipped with adjustable speed settings and temperature controls to maintain the quality of the chocolate.

Another type is the batch enrobing machine, which is suitable for smaller productions or artisanal chocolatiers. These machines are often more compact and versatile, allowing for easy adjustments in terms of coating thickness and various types of enrobing materials. Their smaller size makes them ideal for experimenting with different flavor combinations and for smaller runs without the need for significant investment in large-scale equipment. Additionally, some machines incorporate advanced technology features like automated cleaning systems, reducing the time and labor involved in switching between recipes or colors. Understanding these distinctive features will guide buyers in making an informed decision that aligns with their production goals.

When selecting a chocolate enrobing machine, understanding industry trends is crucial, particularly regarding capacity and efficiency metrics. Manufacturers are increasingly focusing on machines that can handle high volumes of production without compromising on quality. This aligns with the growing demand for chocolate products in the market, making efficiency a top priority. Buyers should look for machines that feature adjustable throughput rates, ensuring they can scale operations according to demand fluctuations.

Tips for buyers: Always assess the machine's production speed and its output capacity. A well-balanced enrobing machine should not only meet immediate production needs but also have the flexibility to adapt to future growth. Additionally, consider the energy consumption of the machine, as energy-efficient models can significantly reduce operational costs over time.

Another trend is the integration of automation and smart technology in chocolate enrobing machines. Automated systems enhance precision in coating, reduce labor costs, and minimize human error. When evaluating options, buyers should prioritize models that offer user-friendly interfaces and advanced monitoring features. This will not only improve productivity but also ensure consistent quality in the final product.

When selecting a chocolate enrobing machine, buyers must not overlook the crucial aspects of maintenance and operational costs. Proper upkeep is essential for ensuring the longevity and efficiency of the equipment. Regular cleaning and periodic checks can prevent costly breakdowns and ensure optimal performance. Buyers should inquire about the manufacturer's recommendations regarding maintenance schedules and whether they offer support services. Understanding the maintenance requirements upfront can drastically influence long-term operational expenses.

Operational costs also play a significant role in the decision-making process. Factors such as energy consumption, labor needs, and the cost of replacement parts can add up over time. Buyers should analyze the machine's efficiency, including how much chocolate is wasted during the enrobing process. Investing in a machine designed for lower energy use and minimal waste may lead to substantial savings in the long run. Additionally, understanding the compatibility of the machine with different types of chocolate and other ingredients can impact overall production costs, making it essential for buyers to evaluate these considerations closely prior to purchase.

When considering the right chocolate enrobing machine, buyers often grapple with the credentials of potential suppliers. As the chocolate machinery market expands, it is crucial to evaluate suppliers thoroughly to ensure quality, reliability, and innovation. One effective strategy is to look for suppliers with recognized certifications that validate their expertise and commitment to industry standards. This not only enhances the buyer's confidence but also assures that the machines adhere to safety and quality regulations.

In addition to certifications, exploring a supplier's track record in customer satisfaction can provide valuable insights. Engaging with existing customers can reveal their experiences and the long-term performance of the machinery. Buyers should also assess the supplier’s service offerings, such as training and support, to ensure they will receive ongoing assistance post-purchase. By focusing on these best practices, buyers can make informed decisions, ultimately leading to successful investments in chocolate enrobing technology that meets their production needs.

For more information, fill out our contact form