In the ever-evolving confectionery industry, the demand for high-quality chocolate products continues to rise, with the global chocolate market projected to reach a valuation of approximately $162 billion by 2024, according to industry reports. To keep pace with this growth, businesses must invest in efficient production equipment, crucially the Chocolate Mixing Machine. This essential piece of machinery not only impacts the quality and consistency of the final product but also plays a significant role in optimizing operational efficiency. Selecting the right Chocolate Mixing Machine can make a substantial difference, as the right model can enhance flavor profiles, streamline production processes, and ultimately contribute to a higher profit margin. Therefore, understanding the key features and technological advancements in chocolate mixing machines is critical for any business aiming to thrive in this competitive market.

When selecting a chocolate mixing machine for your business, several key factors must be considered to ensure optimal performance and productivity. According to the latest industry report from Grand View Research, the global chocolate market is expected to reach $230 billion by 2024, highlighting the increasing demand for efficient mixing equipment. One of the primary factors to consider is the machine’s capacity. Businesses must assess their production volume requirements, as a machine that is too small can hinder output while one that is too large may lead to unnecessary investment.

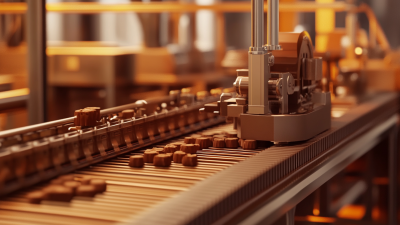

Another critical aspect is the type of mixing technology used in the machine. Different machines utilize various mixing methods, such as agitators, ribbon mixers, or conical mixers, each offering distinct advantages for different chocolate formulations. A report by MarketsandMarkets indicates that the demand for conical mixers is rising due to their ability to produce homogenous mixtures while minimizing shear, making them ideal for sensitive chocolate blends. Additionally, energy efficiency should not be overlooked; selecting a machine that consumes less power can lead to significant cost savings over time, aligning with the industry trend towards sustainable production practices.

When choosing the best chocolate mixing machine for your business, it's crucial to compare the various types available on the market, each with its unique advantages and disadvantages. For instance, traditional ribbon blenders offer uniform mixing and are often cost-effective, making them ideal for smaller operations. However, they may not achieve the same consistency in texture as more advanced machines. On the other hand, high-shear mixers are renowned for their ability to produce a smooth and creamy chocolate consistency, essential for premium products. While they can come with a higher price tag, the investment often pays off in product quality.

Additionally, continuous mixers can drastically improve production efficiency, allowing for larger batches in less time. However, they require substantial space and can be more complex to operate, which may not be practical for all businesses. It's also important to consider energy consumption and maintenance costs, as these factors will impact your overall operational budget. Carefully weighing these pros and cons ensures you select a machine that not only fits your current needs but also supports future growth in your chocolate business.

This chart compares the mixing efficiency of various types of chocolate mixing machines, showcasing performance ratings from different categories. Batch mixers have a lower efficiency rating compared to continuous mixers, which are the most efficient in this comparison.

When selecting a chocolate mixing machine for your business, understanding the essential features is crucial to ensure optimal performance and product quality. According to a report by the International Cocoa Organization, the global demand for chocolate is expected to rise by 5% annually. This increasing demand places more importance on efficiency and consistency in chocolate production. A top-notch mixing machine should have precise temperature control, which helps in achieving the desired viscosity and texture. Machines equipped with programmable settings allow businesses to replicate formulas consistently, aiding in maintaining product quality.

Another important feature to look for is the capacity and scalability of the chocolate mixing machine. Industry data suggests that companies looking to expand should consider machines that accommodate larger batches without compromising quality. A report from Research and Markets indicates that the chocolate processing equipment market will reach USD 5.75 billion by 2025, highlighting the need for businesses to invest in advanced machinery that can handle variable production scales. Additionally, ease of cleaning and maintenance should not be overlooked, as these factors contribute to the overall efficiency and longevity of the equipment. Choosing a machine with detachable parts and user-friendly interfaces can save valuable time and resources, allowing businesses to focus on growth and innovation.

When selecting a chocolate mixing machine for your business, assessing its efficiency and capacity is crucial to ensuring optimal production. Efficiency can be evaluated by examining the machine's mixing speed and uniformity. A high-speed mixing machine can significantly reduce production time, while a design that promotes even mixing prevents segregation of ingredients, resulting in a consistent product. It's also essential to consider the energy consumption of the machine; lower energy use not only cuts costs but also signifies a more efficient model.

Capacity, on the other hand, refers to the volume of chocolate the machine can handle in a single batch. This measurement is vital for understanding how well the machine meets your production demands. A machine that can accommodate larger batches may expedite your workflow and reduce downtime. However, it’s important to balance capacity with the flexibility to handle smaller batches, especially if you produce a variety of chocolate products. Assessing both efficiency and capacity will help you choose a mixing machine that aligns with your business goals and enhances productivity.

When investing in mixing equipment for your chocolate business, a critical consideration is the balance between cost and quality. It's tempting to choose lower-priced options, especially for startups, but the long-term benefits of quality equipment often outweigh initial savings. Quality mixing machines can enhance the consistency and flavor of your product, significantly impacting customer satisfaction and repeat business. As seen in recent comparisons of various kitchen equipment, those that invest in high-quality mixers generally find that their products not only perform better but also last longer, providing greater value over time.

Moreover, the growing market for industrial mixers indicates that businesses are increasingly recognizing the importance of investing wisely in their production capabilities. With the global market for mixers projected to expand significantly, selecting a durable and efficient machine can be seen as a strategic advantage. Factors like the machine's versatility, ease of use, and maintenance requirements are also vital in making an informed decision. By prioritizing quality and functionality in your equipment choices, you'll ensure that your chocolate mixing process meets both production needs and quality standards, setting your brand up for success in a competitive market.

| Model | Capacity (kg/h) | Price (USD) | Material | Energy Consumption (kW) | Warranty (Years) |

|---|---|---|---|---|---|

| Model A | 100 | $15,000 | Stainless Steel | 10 | 3 |

| Model B | 150 | $22,000 | Aluminum | 15 | 5 |

| Model C | 200 | $30,000 | Stainless Steel | 20 | 5 |

| Model D | 250 | $40,000 | High Tensile Steel | 25 | 7 |

For more information, fill out our contact form