In today's fast-paced confectionery industry, the integration of technology has become a crucial factor for enhancing production efficiency and maintaining product quality. A recent report from the International Confectionery Association highlighted that the global chocolate market is projected to reach $162.5 billion by 2024, with significant growth driven by the increasing demand for innovative products and sustainable production processes. As manufacturers strive to keep pace with consumer preferences, the adoption of advanced robotics, particularly Chocolate Robots, has emerged as a game-changer in optimizing production lines.

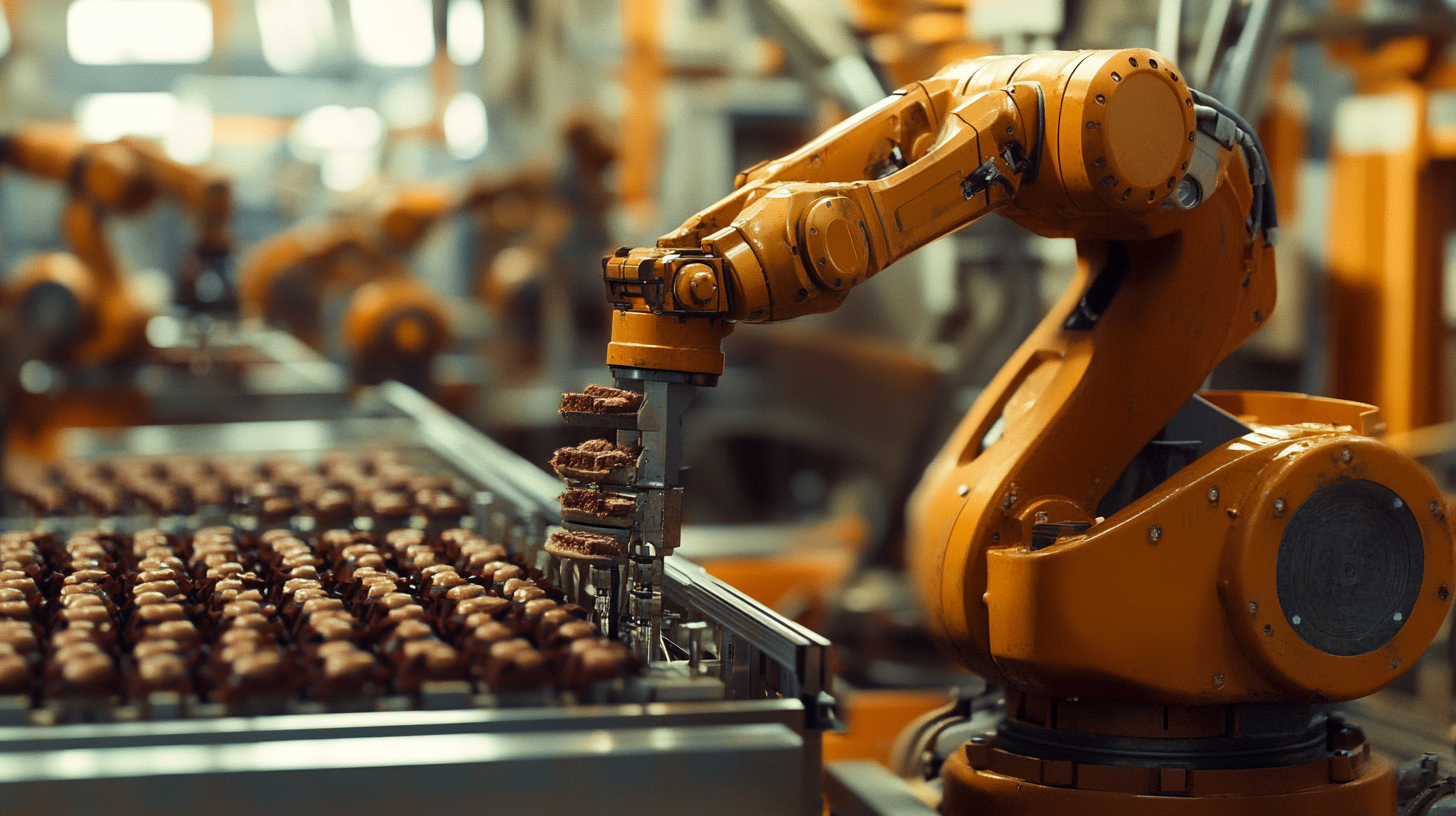

Chocolate Robots are revolutionizing the way chocolate products are manufactured, offering precise control over mixing, tempering, and molding processes. According to a study published by Market Research Future, the robotics market in the food and beverage sector is expected to experience a compound annual growth rate (CAGR) of 12% from 2021 to 2027. By implementing Chocolate Robots, companies can not only enhance operational efficiency but also reduce labor costs and minimize human error, resulting in higher productivity and better product consistency. This guide seeks to explore the best practices for integrating Chocolate Robots into production lines, ensuring that manufacturers can capitalize on the potential of automation while meeting the rising demands of the chocolate market.

The integration of chocolate robots in modern production facilities has become a crucial aspect of enhancing efficiency and productivity. As the chocolate industry continues to evolve, manufacturers are increasingly turning to automation to meet the rising consumer demand. According to a report by Grand View Research, the global chocolate market is expected to reach approximately $162.2 billion by 2024, growing at a CAGR of 4.7%. This surge highlights the need for streamlined production processes where chocolate robots play a pivotal role. Chocolate robots are designed to automate various stages of production, from mixing ingredients to packaging finished products. This automation not only speeds up the production line but also minimizes human error, which can lead to product inconsistencies. A study by Research and Markets found that automation can improve operational efficiency by 30-40%, allowing manufacturers to produce higher volumes without compromising quality. Furthermore, the use of robotics in chocolate production helps in maintaining hygiene standards, as these machines can operate in controlled environments, reducing the risk of contamination. The versatility of chocolate robots also enhances customization capabilities. With consumers increasingly looking for unique flavors and shapes, manufacturers can utilize robotics to produce a diverse range of products on the same line. IBM's latest report on consumer preferences indicated that 70% of chocolate consumers are interested in unique offerings. This trend encourages chocolate producers to adapt quickly to market demands, making chocolate robots an essential investment in modern production facilities.

In the evolving landscape of chocolate production, automation is becoming indispensable. Recent reports indicate that implementing robotic systems in manufacturing can increase productivity by up to 25% while reducing operational costs by around 15%. The integration of chocolate robots streamlines production processes, ensuring consistency in quality and output. With consumer demand for high-quality chocolates on the rise, these robots enable manufacturers to meet this demand swiftly and efficiently.

One key advantage of automating chocolate production is enhanced precision. Data from the International Cocoa Organization shows that thorough consistency in chocolate texture and flavor is crucial for customer satisfaction. Robotic systems, equipped with advanced sensors and AI capabilities, minimize human error and ensure that each batch of chocolate meets strict quality standards. Furthermore, machines can operate around the clock, leading to significant time savings and the ability to scale production without sacrificing quality.

Another benefit lies in waste reduction. According to a report by the Food Processing Technology journal, companies that deploy automated systems can reduce ingredient waste by up to 20%. This not only has a positive impact on profitability but also aligns with the growing trend towards sustainable manufacturing practices. Overall, the integration of chocolate robots is not only a step towards greater efficiency but also a pathway for manufacturers to stay competitive in a rapidly changing market.

In the quest for maximizing efficiency in chocolate production, integrating robots specifically designed for this purpose is paramount. When selecting chocolate robotics solutions, there are essential features that can make or break the performance of these systems. One of the most crucial aspects is the ability of the robot to handle delicate chocolate materials without compromising quality. This includes features like precise temperature control and gentle handling mechanisms that prevent breakage or melting during the processing stages.

Another vital feature is the adaptability of the robotic system. The production line must be able to accommodate various chocolate types and forms, from bars to truffles. Look for robots with programmable settings and flexible designs that can quickly switch between tasks without extensive downtime. This flexibility not only boosts production efficiency but also responds to market demands more effectively.

Additionally, the seamless integration of advanced AI functionalities is essential for real-time monitoring and optimization of processes. Robotics solutions that leverage AI can analyze production data on the fly and adjust operations to enhance quality and reduce waste. By focusing on these essential features, manufacturers can unlock the full potential of chocolate robotics, leading to more efficient and profitable production lines.

Integrating chocolate robots into your production line can significantly enhance efficiency, but the success of this transition relies heavily on effective implementation strategies. The first step in a seamless integration process is conducting a thorough assessment of existing systems. This involves analyzing current workflows, identifying bottlenecks, and determining how chocolate robots can complement or replace manual processes. By understanding the unique demands of your production environment, you can tailor the integration process to fit your specific needs.

Next, it’s crucial to prioritize compatibility and communication between your new robotic systems and your existing machinery. Invest in technology that offers flexible programming options and compatibility with various software platforms. This ensures that data exchange between robots and other systems is seamless, allowing for real-time monitoring and adjustments. Training your staff to operate and troubleshoot these robots is equally important. Setting up a robust training program will empower your employees, equipping them with the skills needed to harness the full potential of your new technology.

Finally, consider a phased approach to implementation. Instead of overhauling the entire production line at once, gradually introduce the chocolate robots to test their integration in isolated sections of your operation. This allows for necessary adjustments and fine-tuning without disrupting overall productivity. By taking these careful and strategic steps, you can unlock the true potential of chocolate robots, leading to greater efficiency and productivity in your production line.

The chocolate industry is undergoing a significant transformation, driven by innovations in robotics and automation that aim to enhance production efficiency. According to a report by MarketsandMarkets, the global chocolate market is projected to reach $161.56 billion by 2024, growing at a CAGR of 4.9%. This growth is prompting manufacturers to adopt advanced technologies that can streamline production processes and meet increasing consumer demands.

Emerging trends in chocolate robotics, such as the integration of Artificial Intelligence (AI) and machine learning, are revolutionizing the way production lines operate. For instance, robots equipped with vision systems can identify imperfections in chocolate products, ensuring only the highest quality makes it to consumers. A recent study by The Association for Packaging and Processing Technologies (PMMI) highlighted that automated systems can improve production speeds by up to 30%, illustrating the impact that robotics can have on operational efficiency.

Moreover, innovations in collaborative robots (cobots) are making it simpler for chocolate manufacturers to adapt to varying production demands. Cobots can work alongside human operators, assisting in tasks such as packaging and quality control without the need for extensive reconfiguration of the production line. The International Federation of Robotics predicts that the use of cobots in the food industry will increase by 60% in the next few years, reflecting the trend towards a more integrated and responsive manufacturing environment.

As chocolate production continues to evolve, staying ahead of these trends will be essential for companies looking to maintain a competitive edge. Embracing automation not only enables manufacturers to optimize their operations but also opens new avenues for innovative product development and enhanced consumer satisfaction.

For more information, fill out our contact form