In the ever-evolving world of confectionery production, the Chocolate Packing Machine stands out as a pivotal component that ensures product integrity and efficiency. As manufacturers strive to meet growing consumer demands, understanding the specifications of these machines becomes essential for optimizing their operations. This blog explores the intricate details of Chocolate Packing Machines, delving into the various specifications that set different models apart. By unlocking these secrets, we aim to equip producers with the knowledge to make informed decisions about their packaging equipment.

Furthermore, the optimal usage of Chocolate Packing Machines can greatly enhance production capabilities while maintaining the quality of the final product. From material compatibility to speed and efficiency, each aspect plays a significant role in the success of chocolate packaging. This guide will provide valuable insights into maximizing the machine's potential, ensuring that businesses not only meet production targets but also elevate their brand's standing in a competitive market. Join us as we navigate through the complexities of Chocolate Packing Machine specifications and uncover strategies for optimal usage.

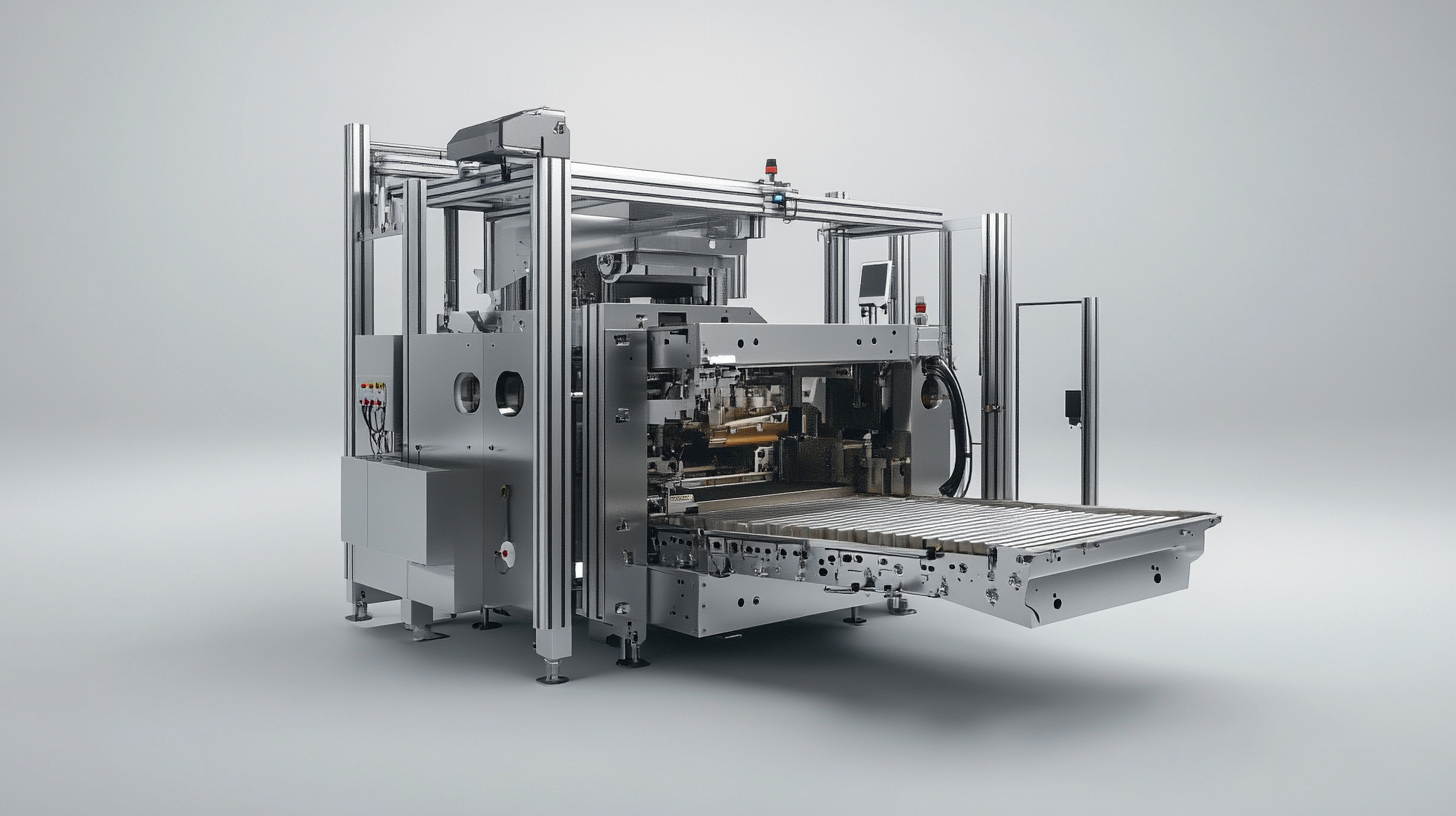

When it comes to selecting the right chocolate packing machine, understanding the specifications is crucial for ensuring efficiency and quality in packaging. Key metrics to consider include the machine's speed, which is typically measured in bags per minute. An efficient packing machine should accommodate your production volume while maintaining consistency and minimizing downtime. Operators should also assess the machine's adaptability to different types and sizes of chocolate products, from bars to truffles, to maximize flexibility in production lines. Another vital specification is the sealing mechanism. Effective sealing helps maintain the freshness of chocolate, preventing contamination and extending shelf life. Various sealing technologies, including heat sealing and ultrasonic sealing, have distinct advantages depending on the packaging materials used. Therefore, understanding the sealing options can significantly impact packaging quality and overall product integrity. Additionally, ease of maintenance is a considerable aspect when evaluating chocolate packing machines. Machines designed with user-friendly interfaces and accessible parts for cleaning and maintenance can reduce operational disruptions and improve productivity. As you explore different machines, be sure to consider their compatibility with automation systems and integration with existing production processes, enhancing efficiency and streamlining operations in the long run.

In the chocolate packaging industry, speed and efficiency are paramount factors that significantly influence productivity and profitability. According to a report by the Freedonia Group, the demand for automated packaging machinery is projected to grow by 6.8% annually, driven largely by the need for higher speed and operational efficiency. As chocolate manufacturers increase production to meet consumer demand, optimizing the packaging process becomes essential.

Modern chocolate packing machines can achieve speeds of up to 300 packages per minute, a drastic improvement compared to manual packing methods. This shift not only accelerates the packaging process but also ensures a consistent quality of each package, reducing the likelihood of errors that can occur with manual labor. For example, a high-speed horizontal form-fill-seal (HFFS) machine can effectively cut down packaging time, providing a direct competitive edge for companies that implement these advanced technologies.

Additionally, efficiency in chocolate packaging operations extends beyond speed; it encompasses the optimization of materials used and energy consumption during the packaging process. A comprehensive study by Smithers Pira highlights that energy-efficient machines can reduce operational costs by up to 30%. With sustainability in mind, manufacturers are not only able to improve profit margins but also align their operations with growing environmental considerations by utilizing biodegradable packaging materials in conjunction with efficient machinery.

Therefore, embracing the right chocolate packing machine specifications is critical for businesses looking to enhance their packaging operations. Speed combined with efficiency allows these companies to stay ahead in a rapidly evolving market while also appealing to eco-conscious consumers.

When it comes to chocolate packaging, selecting the right materials is crucial in preserving both the quality and appeal of the product. The primary objective is to ensure that the chocolate remains fresh, prevents contamination, and maintains its glossy appearance. Different types of packing materials offer unique benefits, hence why compatibility with chocolate’s characteristics is vital. For instance, heat-sealable films, made from materials like polyethylene or polypropylene, provide an excellent barrier against moisture and oxygen, thus extending the shelf life of the chocolate.

Additionally, it is important to consider factors such as the chocolate’s form—whether it’s bars, chunks, or bonbons—as this can influence the choice of packaging materials. Rigid containers might be suitable for chocolate bars, while flexible pouches work well for smaller pieces or bulk products. Biodegradable and compostable options are becoming increasingly popular in the industry, aligning with sustainability trends and consumer preferences. These materials not only protect the chocolate but also convey an eco-friendly message that resonates with today’s environmentally conscious consumers.

Furthermore, aesthetics play a pivotal role in packaging. The chosen materials should ideally enhance the visual appeal of the product through elegant designs and vibrant colors. Laminated films and glossy finishes can attract consumers' attention while showcasing the premium nature of the chocolate inside. Therefore, understanding the interplay between material properties and the specific requirements of chocolate packaging is critical for manufacturers aiming to ensure quality, extend shelf life, and create an impactful presence on the store shelf.

When it comes to ensuring the quality and freshness of chocolate, selecting the right packing machine settings is crucial. Factors such as temperature, humidity, and sealing techniques play a significant role in maintaining the delicate flavors and textures of chocolate. Using a packing machine designed specifically for chocolate can help safeguard against external elements that could compromise its integrity.

To enhance the preservation of chocolate, it is important to set the machine to an optimal temperature range. Ideally, chocolate should be packed at a temperature that prevents condensation while still allowing for efficient sealing. Furthermore, maintaining a controlled humidity level can prevent moisture absorption, which can lead to bloomed chocolate or altered textures. Employing an airtight sealing method not only protects against moisture but also prevents the chocolate from absorbing unwanted odors from the environment, keeping its flavor profile intact.

Additionally, choosing the right packaging materials is essential for optimizing freshness. Using materials that offer both light and oxygen barriers will further protect the chocolate from degradation. Pay attention to the type of film used; it should be food-safe and designed to enhance shelf life. By fine-tuning these machine settings and material choices, manufacturers can effectively extend the freshness of their chocolate products, ensuring that consumers enjoy the best possible experience.

When it comes to chocolate packing machines, maintenance is key to ensuring optimal performance and longevity. Regular upkeep not only enhances efficiency but also minimizes downtime, allowing businesses to meet production demands without interruption. One essential tip for maintaining chocolate packing equipment is to keep all components clean. Residue or buildup can lead to malfunctions and impact the quality of packaged products. Implementing a regular cleaning schedule can help prevent these issues and maintain the machine's effectiveness.

Another crucial aspect of maintenance is inspecting the machine's mechanical parts. Over time, components may wear down or become misaligned, which can result in packaging errors. Regularly checking for signs of wear, lubricating moving parts, and tightening loose bolts can go a long way in extending your equipment's lifespan. It's also important to stay updated on any software or firmware upgrades, as these can improve the machine's functionality and fix existing bugs.

Finally, operator training is an integral part of chocolate packing machine maintenance. Ensuring that all personnel are familiar with the machine's specifications and operational guidelines will not only increase productivity but also reduce the risk of accidental damage. Well-trained operators can identify potential issues early and address them before they escalate, thus safeguarding the functionality of your chocolate packing equipment for years to come. By focusing on these maintenance strategies, businesses can unlock the full potential of their chocolate packing machines and ensure a steady flow of high-quality products.

For more information, fill out our contact form