In recent years, the global chocolate market has seen remarkable growth, driven by increasing consumption and demand for quality products. The chocolate industry is projected to reach a value of approximately $162 billion by 2024, with a compound annual growth rate (CAGR) of around 4.6% (Statista). This surge has led to an enhanced focus on packaging solutions, particularly with chocolate packing machines that ensure product integrity and appeal. Chinese manufacturers have emerged as key players in this sector, offering advanced technology and efficient production capabilities. As the market expands, the role of high-quality chocolate packing machines becomes critical, supporting brands in meeting consumer expectations for freshness and presentation while navigating the complexities of international markets. This blog tutorial aims to explore how leveraging Chinese quality in chocolate packing machines can drive global success for chocolate manufacturers.

The global chocolate market is witnessing significant growth, driven by rising consumer demand and evolving preferences for premium and artisanal products. According to a recent report by Research and Markets, the global chocolate market is projected to reach $161.56 billion by 2024, growing at a CAGR of 4.6% from 2019. This growth presents an excellent opportunity for automation in chocolate packing machines, which are crucial for enhancing production efficiency and maintaining product quality.

As manufacturers aim to keep pace with increasing chocolate consumption, automating the packing process can help streamline operations and reduce labor costs. An illustration of this trend can be seen in a report by the International Federation of Robotics, which indicates a 12% increase in the use of industrial robots in food packaging, including chocolate. These advancements not only boost operational efficiency but also ensure precise and consistent packaging, which is vital for meeting consumer expectations in a competitive market. By integrating state-of-the-art packing machinery, companies can better position themselves to capitalize on the booming global chocolate sector.

In the ever-evolving landscape of confectionery manufacturing, high-quality chocolate packing machines play a crucial role in maintaining product integrity and maximizing efficiency. According to a recent industry report by MarketsandMarkets, the global chocolate packaging market is projected to reach USD 4.98 billion by 2026, driven by rising consumer demand for premium chocolate products. To meet this demand, manufacturers must focus on key technical parameters that define their machines' performance.

One critical parameter is the speed of the packing machine, which often surpasses 200 packs per minute for high-capacity models. This capability not only enhances throughput but also ensures a consistent product output. Additionally, precision in filling volume is essential—machines with an accuracy of ±1% are now standard in the industry.

Furthermore, the flexibility to handle various packaging formats, from flow packs to sealed pouches, has become increasingly important. Modern machines often utilize advanced control systems that integrate real-time monitoring, allowing for immediate adjustments during production runs, thus minimizing downtime and waste. These innovations highlight how Chinese manufacturers are leading the way in delivering quality packaging solutions that meet global standards.

When selecting the right chocolate packing machine for your production needs, there are several critical factors to consider. First and foremost is the type of chocolate product you are manufacturing—whether it’s bars, pralines, or bulk chocolates. Different designs and technologies are suited for various forms of chocolate, so identifying the appropriate machine that can handle your specific product will ensure efficiency and quality.

Another important aspect to consider is the packaging material. With the growing emphasis on sustainability, choosing machines that accommodate eco-friendly packaging options is becoming increasingly vital. For instance, innovations in paper packaging solutions have emerged, allowing manufacturers to maintain the integrity of their chocolate while adhering to environmental goals. Furthermore, machine efficiency and speed are crucial, particularly in meeting production targets without sacrificing quality. Thus, assessing the machine’s capabilities for throughput and ease of operation will enable you to scale your production effectively.

Investing in Chinese technology for

chocolate packaging solutions has become an increasingly

popular choice for manufacturers around the world. One of the primary benefits is the

cost-effectiveness of Chinese packaging machines.

These machines offer high-quality production at a fraction of the cost compared to their

Western counterparts, allowing businesses to allocate their resources more efficiently.

The competitive pricing does not compromise quality; instead, it ensures that companies can

produce superior products while maintaining profitability.

Another significant advantage is the

rapid technological advancements in Chinese manufacturing.

These innovations lead to improved

efficiency,

sustainability, and

flexibility in chocolate packaging processes.

Chinese manufacturers are continually upgrading their machinery to incorporate the latest technology,

such as automation and smart systems, which enhance production speed and reduce waste. By embracing

these advancements, chocolate producers can stay ahead of the competition and meet the ever-evolving

demands of consumers. This alignment with modern technology not only streamlines operations but also

fosters a more sustainable production environment, making it a win-win

for both manufacturers and the planet.

In recent years, the global market for chocolate packing machines has witnessed a significant transformation, driven by the increasing demand for high-quality packaging solutions.

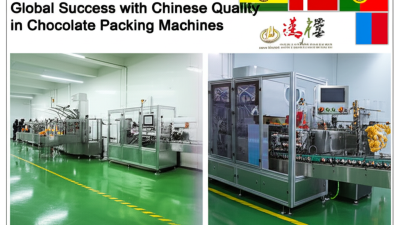

Chinese packing machines have made a remarkable impact internationally, showcasing their innovative technology and efficiency. Case studies from various markets highlight how these machines have helped businesses enhance their production capacities and improve packaging quality, effectively meeting the evolving needs of consumers.

The success stories of Chinese chocolate packing machines span multiple countries, illustrating their adaptability and effectiveness in diverse environments. For instance, companies that have integrated these advanced machines into their operations report increased productivity and reduced operational costs. The emphasis on automation and precision in Chinese manufacturing practices allows businesses across the globe to stay competitive. As the world increasingly seeks efficient and sustainable packing solutions, the implementation of Chinese chocolate packing machines could prove to be a game changer, facilitating growth and success in the chocolate industry.

For more information, fill out our contact form